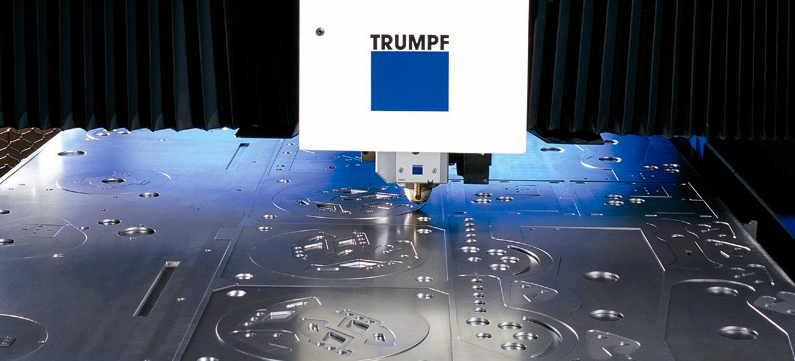

Tips for laser cutting

It’s not too hard to find a laser cutting firm that will do small orders and offer very rapid turn around. The precision, quick turn around, and the ability to work without proper CAD files make it an attractive option for making custom parts.

We’ve used laser cutting for project enclosures, anesthesia tube holders, light tight barriers, and other rigging.

If the parts you need can be assembled out of flat pieces of plastic, then you’re in business. If it has to be metal, you’re better of going to a CNC machine shop. If it has to be some complex 3D shape, but can be plastic, then 3D printing is the way to go. But if you can make your part out of flat pieces of plastic, laser cutting is the way to go.

Note: Most of these tips also apply to water jet cutting firms. Water jets can cut a lot of things that lasers can’t: metal, glass, foam, and anything that gives off toxic fumes when burned.

1. Find a laser cutting firm.

Just search on the Internet using the terms “laser cutting” or “laser cutting services”. Contact them, tell them who you are and that you’re looking for a laser cutting firm for your small, one-off jobs. Also ask if they’ll work from sketches or simple drawings. Most places are happy to take this kind of work, but in rare cases a firm will be more industrially focussed. In the UK, we’ve used this firm:http://www.cut-tek.co.uk/

2. Pick a material.

You can check to see what the firm has in stock. Black or clear acrylic are commonly used. Thickness are typically 1-3mm. But be aware that the material thickness is typically not terribly precise. Ask them to measure it for you if it’s critical. Otherwise, just assume that it may vary up to 10% from the stated thickness.

3. Draw the pieces you need in your favorite drawing software.

Adobe Illustrator and Microsoft Powerpoint are popular options. Make sure that you mark all of the dimensions. The drawing doesn’t have to be perfectly to scale, as long as all the dimensions are marked. The laser cutting firm will redraw it in their own program. If your parts have particularly intricate designs, you should consult with the laser cutting firm to see if they prefer a certain file format.

4. Send the order off.

Make sure your drawings have no ambiguities. Make sure you’ve selected the correct materials. If you’ve selected materials that the laser cutting firm doesn’t have in stock, you’ll have to wait for them to get them in. Alternatively, you can buy the material yourself and ship it to them.

5. Wait for your parts.

This should typically only be 1-5 days. But if they have to wait for material to come in, that will of course lengthen the lead time. So I always try to use materials they have in stock.

6. Put your parts together.

We usually use superglue to had the acrylic parts together. But it is possible to drill and tap holes in acrylic, just drill slow because it is easy to crack acrylic. Special drill bits are sold for drilling acrylic, but these aren’t a necessity. Putting a piece of masking tape on the acrylic sometimes helps with preventing cracking and ensuring that the drill bit stays on target (rather than slipping off).

If you set up a good working relationship with a laser cutting firm, you’ll find it’s a very convenient, fast, and cheap way to rapidly rig something up.

More tips

Box designs

We typically make rather simple box designs. We like to attach the top with magnets for easy access. We also prefer clear acrylic so that we can always see what’s inside. However, if you’re interested in more complex box designs, Curious Inventor has a blog entry with some creative ideas. http://www.curiousinventor.com/blog/27

Mocking up

It is useful to mock things up using cardboard or stiff card stock from an office supply store. These can be cut to approximate dimensions with razor blades or scissors and give some idea of how parts will fit together.

Make extras

Laser cutting is pretty cheap. So if you’re having trouble deciding on a particular dimension, just order the same piece in multiple sizes and then you can decide what you have all the pieces together.

Other than acrylic materials, what other materials can a laser cutting machine cut through? I have a few things that are made out of steel and aluminum. With those my grandson wants me to laser cut them and create a box out of it. http://www.rapidlaser.com.au