Glass is dead

Humankind is overdue for moving past glass for state-of-the-art optics. We’re never going to be completely rid of glass, but we have been coasting on 17th century technology for 21st century applications. We have been too slow to develop adaptive optics, metasurfaces, and other technology for focusing light.

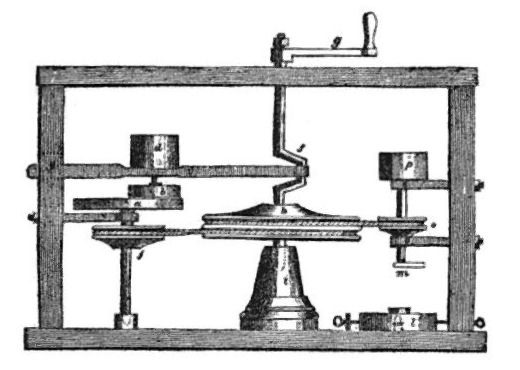

It’s still the same old process. We do a big melt– with materials that would be familiar to glassmakers in 13th century Murano, Italy– and then cut chunks of it out for lensmakers. The lensmaking starts with a rough cut and then gets polished. The fundamental process hasn’t changed much for hundreds of years. We’ve gotten more sophisticated with metrology and the machines that do this, but it is still the same crude process.

Relying on glass lenses is a major constraint for technology. The factories that build glass lens-based systems are high-overhead, low-throughput factories that have to operate in tight margins to be profitable. There is a bit of proprietary know-how in each glass optics company that they use to eke out a profit. But the constraints are tight. I’ve seen how these factories operate. They need to keep a high utilization of the instrumentation. This can be counterproductive for innovation. For example, major microscope companies are vertically integrated– with their own factories, lens making facilities, and even glass companies. This is great for their profit margins overall, but it can stifle innovation as they need to keep their conventional factories running– major changes in tooling or technology are avoided.

Injection molding has gotten good. We can create injection molded lenses with high precision for cheap. This is how cell phone camera lenses are made: submicron-precision aspheric lens assemblies for pennies a piece. The downsides are that (1) tooling costs are massive, (2) it doesn’t work as well for large lenses (> 50 mm), and (3) material choices are limited, which is a major constraint on optical design. All three of these limitations are fundamental. I expect there to be improvements, especially for item 3, but it’s probably always going to be expensive for low-run optics, and not feasible for large dimensions.

Metasurfaces / metalenses are exciting technology. There is a tremendous amount of R&D in academia, but the translation to industrial impact has been slow so far. Academic papers often make impressive performance claims, but are also accompanied by significant handicaps, e.g., high NA, but bad chromatic performance; or good chromatic performance, with crippling aberrations and low transmission. Thus, there is the impression that metalens-based systems are constrained in ways that refractive glass lens-based systems are not. However, I am optimistic about the potential in this area. I think there is a lot of the parameter space left to explore. For example, here is a recent success. Moreover, metalenses can do things that refractive optics cannot do, so it merits broader thinking rather than simply replacing classical refractive lenses.

Adaptive optics are underdeveloped and underutilized. This issue is massive. Tunable lenses, deformable mirrors, liquid crystal-based spatial light modulators, digital micromirror devices, grating light valves, and more. These are impressive technologies with a ton of potential, but they’re built by only a few companies: e.g., grating light valves are made by just one company (Silicon Light Machines), most DMDs are made by TI, most deformable mirrors are made by just a few companies, and only a few companies make liquid crystal spatial light modulators. Thus, the catalog of potential devices is small, and making custom devices is cost-prohibitive. So integration into systems has been slow.

The future could be one in which we build active optical systems. In which multiple adaptive components are combined for focusing light according to an array of system and application parameters. We replace complex assemblies with precision components and tight tolerances with new active components that adapt and compensate for manufacturing imprecisions, diverse applications, and specimen aberrations. Closed loop systems with image processing feeding into routines to rapidly optimize image quality for a broad array of applications.