Mirrors and lenses for multiphoton microscopes

There’s been an interesting discussion on the Confocal listserv, and we’ll quote some of that discussion below. We’ve always used protected gold and silver mirrors for our multiphoton systems. That’s still what we recommend for most neuroscience labs, but it’s worth discussing other types.

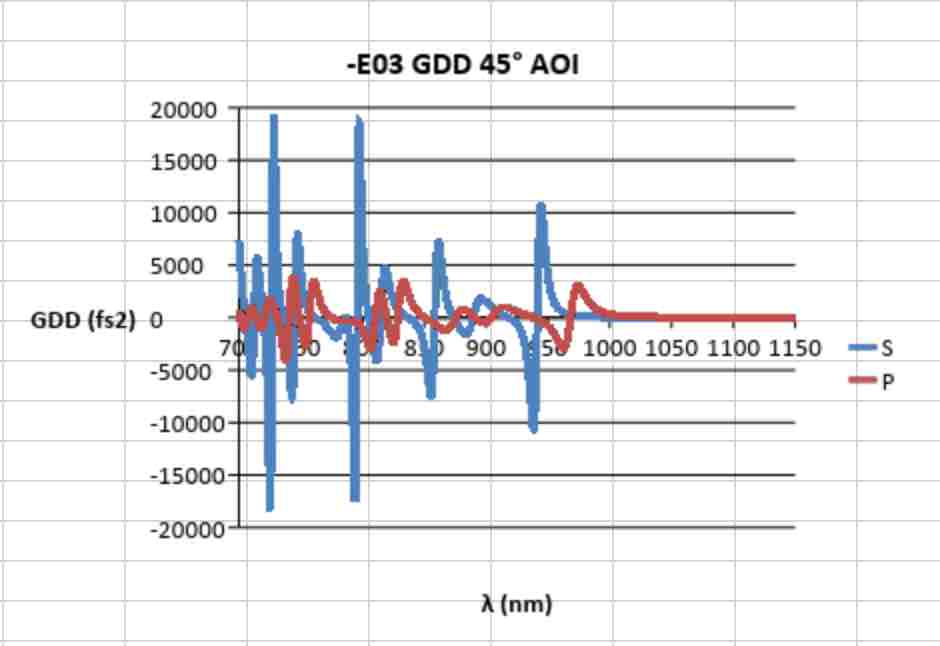

Peter Rupprecht was seeing some strange behavior in his 2p scope (wavelength dependent pulse broadening/dispersion; video here), and traced it back to dielectric mirrors (E03 type, Thorlabs).

From Michael Giacomelli (MIT):

A dielectric mirror is an interference (IIR) filter. For normal reflective mirrors, the phase response isn’t too important and the layers (taps) are optimized for reflectivity and cost. The phase response is whatever the optimizer picks as cheapest, and can be very strange at some wavelengths. They make ultrafast dielectric mirrors that have a specified phase function, both for dispersion compensation (Thor sells these too) or just for high reflectivity without (uncontrolled) dispersion.

I am a little surprised you saw such an extreme response from that one filter, but it’s possible you happened to hit it at a point where the phase response flipped very rapidly from the blue end of your pulse to the red end. Unless you really need high reflectivity, might be worth just using a silver mirror.

By the way, once you get this sorted out, look at those achromats you added as well. Thor gives you the thicknesses and materials, and the dispersions can be looked up here.

The dispersion of individual achromats varies enormously, with tiny differences in focal length sometimes giving very large differences in dispersion. For example, at 900nm, the Thor’s 125mm achromat has double the dispersion (900 vs 470 fs^2) of its 100mm doublet. If you can get away with a singlet, the 100mm LA5817 will give you just 90 fs^2. For this reason I usually try to avoid using stock doublets in ultrafast systems, or if I need them, get ones customized for low dispersion. [In our experience, the aberration correction offered by achromats is worth the increased dispersion, the latter of which can be at least partially dealt with by the pre-chirper. YMMV. -Labrigger]

From Craig Brideau (University of Calgary):

I don’t recommend standard dielectric mirrors for ultrafast applications. The coating is designed for maximum reflectivity with no regard to phase implications. The result can be very unpredictable and in your case clearly led to undesirable higher order dispersion. The best mirrors are protected silver, or if your budget allows, the slightly more expensive ultrafast silver mirrors. Ultrafast dielectric mirrors are also available but these are quite expensive as the coatings are also designed to be nearly phase neutral.

UPDATE (4 June 2018):

David Chen (Postdoc at the Max Planck Institute for Molecular Cell Biology and Genetics) said:

“If you ask Thorlabs, they will provide you the dispersion plots.”

And shared this one for exactly the coating on Peter’s mirror, E03:

(S,P = the perpendicular and parallel polarization directions, respectively. AOI = angle of incidence. GDD = group delay dispersion.)

As you can see, the dispersion varies wildly with wavelength. For many applications, this isn’t a concern, and the extra reflectance from a dielectric coating can be important. But for ultrafast applications, this can be a big problem.

Update:

David Chen (Postdoc at the Max Planck Institute for Molecular Cell Biology and Genetics) said:

“If you ask Thorlabs, they will provide you the dispersion plots.”

And shared this one for exactly the coating on Peter’s mirror, E03:

https://imgur.com/nMgg4AZ

As you can see, the dispersion varies wildly with wavelength. For many applications, this isn’t a concern, and the extra reflectance from a dielectric coating can be important. But for ultrafast applications, this can be a big problem.

Thanks for the really interesting post and update,

During my PhD, I worked primarily on optical coherence tomography (OCT) and designed a few systems. In OCT, you are not necessarily interested in how much you disperse your light as long as you can have the same level of dispersion in both arms of the interferometer. We observed a similar trend with ceramic mirrors, i.e. their dispersion curves were significantly different than standard silver coated mirrors and overall their dispersion was really difficult to compensate.

Some dichroic mirrors also have very peculiar dispersion curves when used in reflection. From my experience, ThorLabs dichroics (I used the DMSP950L) show very strong discontinuities in their dispersion curves, and these curves vary from one dichroic to another. When used in transmission (I used the DMLP950L) the discontinuities were not observed.

So my general rule of thumb was to always use them in transmission and keep the reflection part for widefield imaging or detection. Interestingly I did not see that effect with Chroma dichroics.

I hope this info is helpful!

Cheers,

Paul

Thanks, Paul. Your comment on dichroic mirrors having dispersion effects in reflection and not transmission is an interesting one. The IR dichroics used in 2-photon scopes (to split the excitation and emission paths) are usually IR-passing (aka, “cold mirrors”). The visible light, from the fluorophore, is usually reflected off of the IR dichroic. Dispersion effects for the reflected light are ignorable, but critical for the transmitted IR light. Perhaps this is one reason why 2-photon scopes usually are designed to use cold mirrors instead of hot mirrors.

ThorLabs state that the dielectric coating on their protected silver and gold coatings can affect GDD: “Our standard -P01, -P02, and -E02 coated mirrors are not specified for ultrafast applications, so we do not quantify their GDD from coating run to coating run. In contrast, our -45A and -AG coated mirrors are guaranteed to provide their specified GDD values.” Perhaps the protected gold and silver aren’t as bad as the EO3 mirrors discussed here. I’m a bit cautious about the ultra-fast silver mirrors as I recently saw the silver coating on one fail after only about a year. Maybe unprotected gold is the way to go? https://www.thorlabs.com/images/tabimages/Metal_Coatings_Comparison_45_Degrees_G3-900.gif

I wonder how stable unprotected gold would be in a humid environment. And if I understood it correctly, unprotected metal mirrors cannot be cleaned except by carefully blowing dust away, which is a bit limiting.

I’d also be interested to know how you realized that the coating of your silver mirror failed? Did you see it with your eyes, or from the reflectance performance?

In our experience, protected gold has worked perfectly well for years for use with Ti:Sapph pulses (~ a few watts average, 70-150 fs, 80 MHz). For very fast pulses (e.g., 10 fs), we would expect problems.

We’ve seen protected silver fail, and it’s obvious with direct visual inspection– the mirrors were cloudy. On the basis of specs, protected silver should be better for our application than protected gold. But we use the latter anyways, and have had fewer problems. We cannot back that up with any numbers, and it may just be a fluke.

With this mirror I saw it by eye when I took it out to re-build the set up. I discarded it and swapped it for unprotected gold. That setup has two of those mirrors in the path in the path now. We’ll see how the hold up.

If given lemons, make lemonade. If you have an autocorrelator for measuring under the objective, you can use slight tweaks in wavelength to optimize your pulse width. I don’t remember the exact wavelengths, but we had a system that gave ~300 fs around 920, but at ~924 it was ~130fs. I wouldn’t recommend it as an engineered strategy, but given the spectral width of most fluor under 2P excitation, it is pretty straightforward. Even without an autocorrelator, just do small +-10/15 nm sweeps around desired wavelength, and look at the signal. If it goes up or down anomalously, you are likely around one of those resonances. If nothing much happens, time to borrow that autocorrelator and measure….

In terms of specs I think that the Thorlabs UM10-AG strike a good balance between reflectivity, dispersion and price. They’re supposed to have super low dispersion and reflectivity of 99.5+ % in the 910-1000nm range. I’ve never tested the dispersion, however I find that the reflectivity specs may be a little optimistic, we get more like ~98.5% at 910nm (we tested both P and S pol and found them to be a bit below specs, could be due to our test rig…) Still that’s pretty good, what’s not so good is that a lot of them arrive with defects, I’m not sure if this is specific to the manufacturing process for these mirrors, but in our experience about 30% (!) of them had pinhole size defects in the silver coating. I recommend testing each one of them individually for both reflectivity and also for manufacturing defects. We examine the reflective surface carefully and under front and back illumination (with a small flashlight pressed against the back of the mirror). The pinhole defects are easy to spot when back-illuminating.

[…] dielectric mirrors in the microscope. The lessons learned from that have been summarized before on Labrigger’s blog (also check out the […]