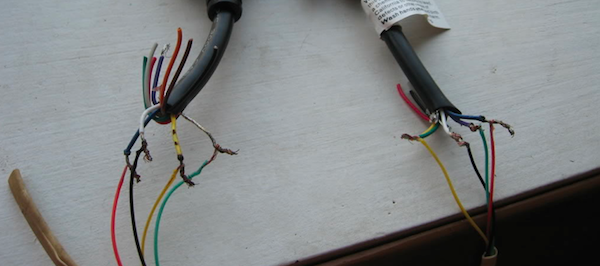

No homemade cables

One of Josh Trachtenberg’s rules that I have adopted is “No Homemade Cables”. It’s so natural to think that this is the best solution to hook two things up: “Wire and bare connectors are so cheap, let’s just make our own cables.” However, homemade cables, even when made with great care, are usually of poor quality compared to commercial cables. As a result, you’re just giving yourself something else to repair in the future.

Option 1

Adapter boxes, aka breakout boxes, are more reliable than homemade cables. If you take this route, put it in a transparent, easy to open box so that you can quickly see (a) how things are wired up, and (b) whether there are any loose connections.

Option 2

Another option is to have custom cables made. I started doing this in London for a rig where I needed two fairly long 48-conductor cables. Custom cables are actually not that expensive and are of very high quality. It’s practical because you don’t have to buy an entire spool of 48-conductor wire (or whatever the job requires); nor do you have to source obscure connectors, strain reliefs, jackets, and whatnot. Not to mention time saved soldering.

Here are a couple of places that you can get quotes from if you’re interested. Any of them will do one-off jobs, you don’t have to bring them volume jobs.

Circuit Assembly

Technical Cable Concepts

Custom Cable Assemblies

[…] previously noted, homemade cables are to be avoided. However, stock cables are not always up to spec. For example, if one wants to drive stepper motors […]