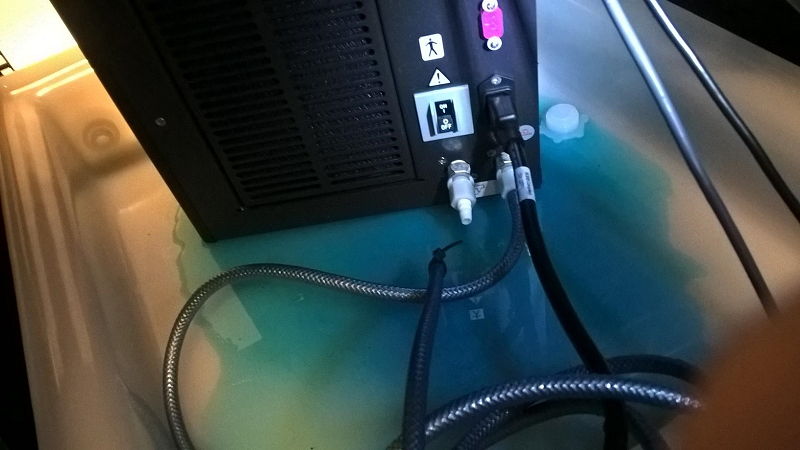

Coolant lines for lasers

Many lasers have baseplates with channels through which chilled water is pumped to dissipate heat and stabilize the temperature of the system. I haven’t had much trouble with the chillers and baseplates of Newport/Spectra-Physics systems. However, most of the Coherent Chameleon systems I’ve worked with (3 out of 4) have had problems with the water chiller and/or baseplate. The chillers broke down and had to be replaced (repeatedly) and/or the baseplates got clogged (which can lead to the tubing popping off, pictured above). What has been your experience?

On the confocal listserv, Craig Brideau recommended household vinegar or a 5% acetic acid solution to clean out a clogged baseplate.

Philip Oshel offered his recipe as well:

I’ve used both hydrogen peroxide and CLR (brand name lime & rust remover). For a TEM-sized chiller, this took one bottle of CLR or 1 Liter of 3% H2O2 (or 100 mL 30% H2O2). Circulate this for one to six hours, or even overnight if needed (sounds like that will be needed in your case), followed by flushing with 4-5 volumes of tap water. This works well, and causes no damage to instrument chilling lines. When I had a biofilm-sludge clogging problem, the vinegar trick worked. I used about 1 Liter of vinegar for this, followed by tap water.

We use Optishield in our chiller water supply to keep it clean. And we flush it regularly. Even that isn’t always enough to avoid problems.

I have essentially solved this problem. When I say “I” what I mean is with the help of Coherent Scotland. Here is the solution:

1. For the one box lasers we have we now use a new chiller that Coherent will supply. We have field tested these for Coherent now for over a year and have had no issue. Ask your sales rep.

2. These chiller came with a different connector line, much larger diameter and red in color. These replace the narrow blue lines shown in the picture.

3. Finally these chiller use a completely different coolant that you must buy from Coherent, called coolflow. This in made in the UK but can only be bought through Coherent in the USA as far as I can establish.

these last 2 strategies have been used with some old chillers (again in picture above) and we have had essentially no issues. So you don’t really need the new chillers!!

I would also add that if you have a Verdi-Mira (we do) then there is a new baseplate with wider supply lines for Verdi which really helps too. Though Coherent still say to use water not coolflow.

I cannot say how painful this has been for my lab for 10 years, but for the past 12 months we have had no issues.

I recommend every 3-4 months replacing the coolflow and blowing out the entire baseplate with nitrogen and some coolflow to ensure it is clean of all particulates. Coherent say you can filter the coolflow and re-use. We simply use fresh.

Can confirm what Graham said above. Had the same problem with Coherent lasers over the years but things have been pretty smooth since we switched to Coolflow. Had it for over a year without much trouble. I would also suggest installing a filter in the coolant lines, the Coherent engineer did this when he installed the new Coolflow chiller.