Rapid prototyping is rapidly maturing

In the past year, since Labrigger’s first post on 3D printing (aka rapid prototyping), the industry has matured dramatically. Most importantly, companies including Shapeways and Ponoko, have opened what used to be a specialist market, up to more mainstream customers, including hobbyists and small operations.

Sculpteo is a new addition. It is tightly linked with 3Dvia, which offers free software for 3D design and an online design sharing system.

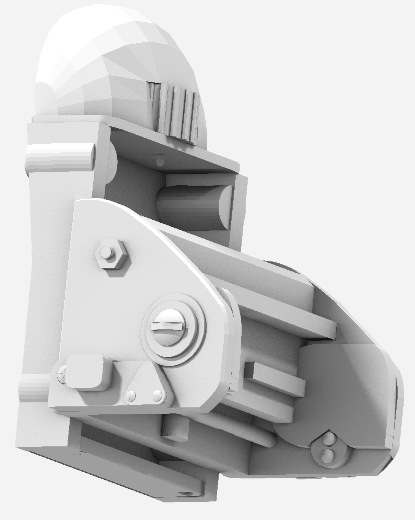

With affordable rates, lots of material options (including metal, pictured above), and decent turnaround times, there’s a lot going for this technology. That said, I wouldn’t recommend getting your own machine. You’re not going to save a ton of time in turn around, all the maintenance and troubleshooting has to be done in house, and you’ll never have as many material options and process options as you can get from a 3D print shop.

3D printing offers very little in terms of economy of scale. This encourages customization, but sometimes you might want 1000 identical parts and not have to pay $20 for each little plastic part. Especially when those parts are disposable or consumable. In that case, limited run injection molding might be the ticket (after you settle on a final design, using 3D printed prototypes). Protomold does production runs from 10-10,000 and prices start around $1500. Turnaround is about 3 weeks.

Another rapid prototyping system that uses a slightly different type of technology is 2BOT’s ModelMaker. It doesn’t print metal, but it has many other useful applications. Take a look at it here: http://www.2bot.com