Project enclosures

Here are some ideas for project enclosures. The stock enclosures from Mouser, Digikey, and others are generally serviceable, but are rarely the perfect size. In addition, making the required cutouts can be inconvenient. Here are a couple of alternatives.

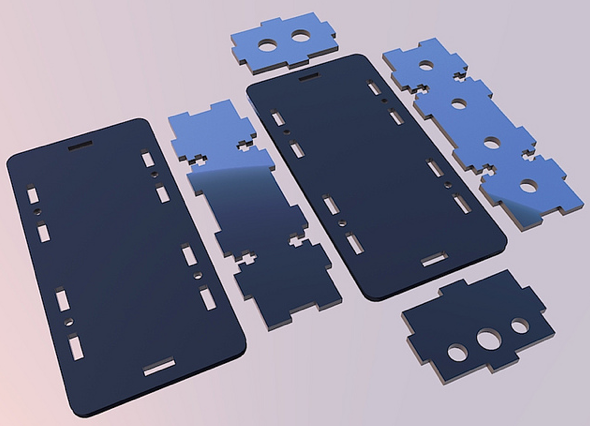

Laser cut an enclosure out of plastic

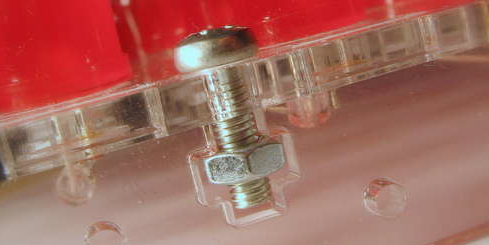

I’ve done this for several projects. It’s cheap, the cutouts are perfect, and there are many different materials that can be used. The downside is that you get 2D panels that you must fasten together. I often use superglue to put the parts together. I’ve also used magnetic strips for panels that need to be removed often. When the material was thick enough, I used screws. Another option is mounting screws and nuts in slots, pictured blow and briefly detailed here.

Here’s an online tutorial example from Rich Decibels (via).

This method offers a way to use screws even when the material is thin. I’m not a big fan of it though, because there are a lot of screws that can easily get loose. Superglue or properly tapped screws are more heavy duty.

Protocase for small run, custom cases

Protocase will make completely custom, sheet metal enclosures with cutouts, painting, and silkscreening. It’s a lot more expensive than laser cutting plastic pieces, but there’s less assembly to be done and they’re more durable. They can make all sorts of shapes, including very nice rackmount chassis.

Ada has a good example of a purely laser-cut enclosure in which pieces snap into one another – no screws:

https://www.adafruit.com/products/859

[…] me about custom enclosures. I thought they wanted something small for electronics, and there are a couple of previous Labrigger posts that could be […]

[…] an open design and 45drives is a division of Protocase, which Labrigger has mentioned […]